WHAT ARE SEALING FASTENERS?

Sealing fasteners are highly specialized fasteners

WHAT ARE SEALING FASTENERS?

Sealing fasteners are highly specialized fasteners that include sealing screws, sealing nuts, sealing bolts and sealing washers. Unlike ordinary fasteners, sealing fasteners are configured with a rubber O-ring (or a rubber element) that when squeezed, permanently seal out a wide range of contaminants from entering and damaging equipment while preventing leakage of toxins into the environment.

THE DIFFERENCE

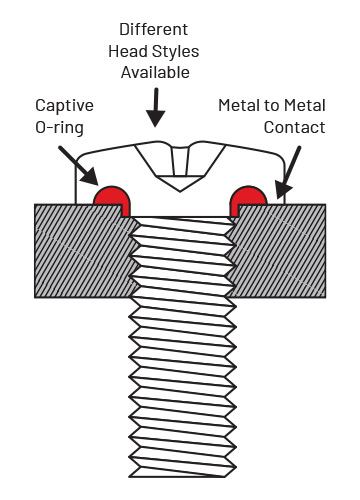

ZAGO high-tech self-sealing fasteners are engineered with a groove under the head of the screw or the face of the nut that when combined with a rubber O-ring and tightened, squeezes outwardly to form a 360-degree leak-proof hermetic seal. The undercut groove ensures that the O-ring will not break or crack once the screw is torqued, and the metal-to-metal contact prolongs the life of the O-ring, which is not compromised under pressure.

SEALING FASTENERS FOR ALL SEASONS

ZAGO sealing fasteners are designed to withstand harsh weather and extreme temperatures, such as when unmanned underwater vehicles survey the icy cold depths of the ocean floor to unmanned automotive vehicles operating in the extreme heat of the desert. They are vibration and pressure-resistant and outperform ordinary fasteners in highly pressurized environments, such as pneumatic pumps used in medical ventilators and pressure valves in industrial machinery.

SEAL IN / SEAL OUT: EQUIPMENT APPLICATIONS

ZAGO sealing fasteners are used in countless industries to seal all sorts of equipment, including:

- Robots and Cobots

- Electric Vehicle Charging Units

- Aircraft Engines & Motors

- Drones and Droneports

- Night Vision Goggles

- Sonar Systems

- Data Centers

- Sensors

- Rechareable Batteries

- Satellites

- Circuit Boards

- 3D Cameras / LiDAR Technology

- Invasive / Non-Invasive Medical Devices

- HVAC Systems

- Conveyor Belts

WHEN TO USE ZAGO SEALING FASTENERS – KEY QUESTIONS

If the answer is yes to any of the following questions, then, it is essential to seal your equipment with sealing fasteners for long-lasting, air-tight, leak-proof protection:

Does your high-asset machinery / sensitive equipment need an air-tight, hermetic seal to:

- Protect itself from exposure to oil, gases, liquids, chemicals, dust, dirt, moisture, salt water or other contaminants?

- Withstand extreme pressure, temperature and/or weather conditions?

- Prevent seepage of pollutants leaking into the environment?

DID YOU KNOW? ZAGO SEALING FASTENERS:

- Most O-ring material have an unlimited shelf life and are available in custom and standard sizes.

- Are reusable, tamper proof and made of corrosion-resistant metals, like stainless steel and steel alloys, titanium, brass and Monel.

- Are compatible with rubber O-rings made of Silicone, Fluorosilicone, Viton, neoprene, buna, Teflon and EPDM.

- Are pollutant-free, made in the U.S.A. and sold worldwide.

- Are available with military and FDA grade O-rings and sealing screws that meet Military Standard NASM 82496 and pressure resistant to 1500 psi.

- Are DFARS, REACH, RoHS and DEKRA compliant and NEMA ready for electrical enclosures.

- Are used in myriad industries, including Robotics & Drones, Military & Aerospace, Agriculture, Medical Device, Telecommunications, Transportation, Marine, Electronics & Enclosures, Commercial Lighting, Energy Generation & Recovery, Heavy Equipment and more.