Features and Use

The use of the flex-hone on firearms

The Flex-Hone quickly and easily creates an optimal “Plateau” surface finish on any type and size of cylinder, guide, chamber, magazine tube, or barrel. It has been in use for decades, and its benefits are proven. “Brush Research Manufacturing” produces a complete line of Flex-Hones for various firearm applications.

The Flex-Hone process is a low-temperature, low-pressure abrasive process that produces a long-lasting surface. This method achieves a surface that is free from metal fragments, smears, or folds, stains, and oxidation. The Flex-Hone creates this finish with minimal micron-level material removal, ensuring that the caliber of your firearms remains at the precise required dimensions. It is easily used with a regular hand drill or rotating spindle, is self-centering, and self-aligns with the bore. Using the Flex-Hone improves the performance and extends the life of your firearms.

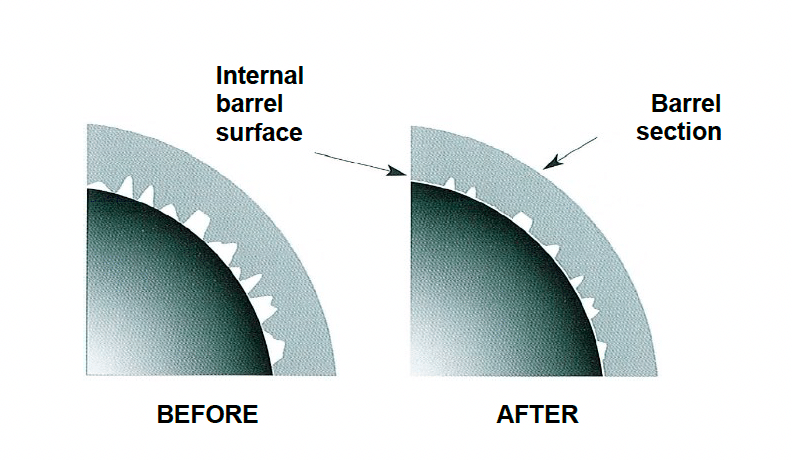

The metal surface of your firearms contains microscopic “peaks” and “valleys.” Corrosion formation is accelerated by residual stresses on the surface. The “Plateau” finish produced by the Flex-Hone refines the “peaks” and reduces surface tension by removing the most stressed areas. The “valleys” produced by the Flex-Hone enhance the surface’s ability to retain oil. Many firearm manufacturers use the Flex-Hone for their final finishing needs.

Not only will your firearms be free of microscopic imperfections, but you will also notice the difference of a perfect finish.