Flex-Hone Features

The Flex-Hone produces a surface finish with characteristics not achievable with other processes. This type of processing involves surface finishing, surface geometry, and metal structure. It achieves a “Plateau” finish with a surface free of ridges, tears, and metal folds. The Flex-Hone also deburrs passage holes while lapping the walls of the bore. In hydraulic or pneumatic applications, it extends the life of sealing gaskets and improves their sealing performance.

The Flex-Hone is a durable and flexible tool with a gentle cutting action. Each of the abrasive balls has independent suspension, allowing the Flex-Hone to be self-centering and self-aligning with respect to the bore and to self-compensate for wear. The Flex-Hone is suitable for all types of bores ranging from 4 to 914 mm in diameter.

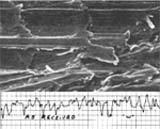

Example of processing with a conventional sander

1000x magnification.

Spreadings and material folds on the surface, which will detach during use.

Finish with many peaks. Characteristics due to the “rigid” sanding action.

After Flex-Hone® usage

Silicon carbide grit #180

1000x magnification

Uniform cross-hatch pattern.

Clean and open appearance with spreadings and material folds removed.

Excellent semi-plateau profile, with few peaks and many valleys for lubricant retention.

Advantages

• “Plateau” finish over 60%

• Cross-hatch pattern finish

• Better lubricant retention

• Reduction of Ra Rpk and Rvk values

• Increased contact surface

• Lower lubricant consumption

• Reduced Blow-By

• Reduce friction

• Improved surface retention

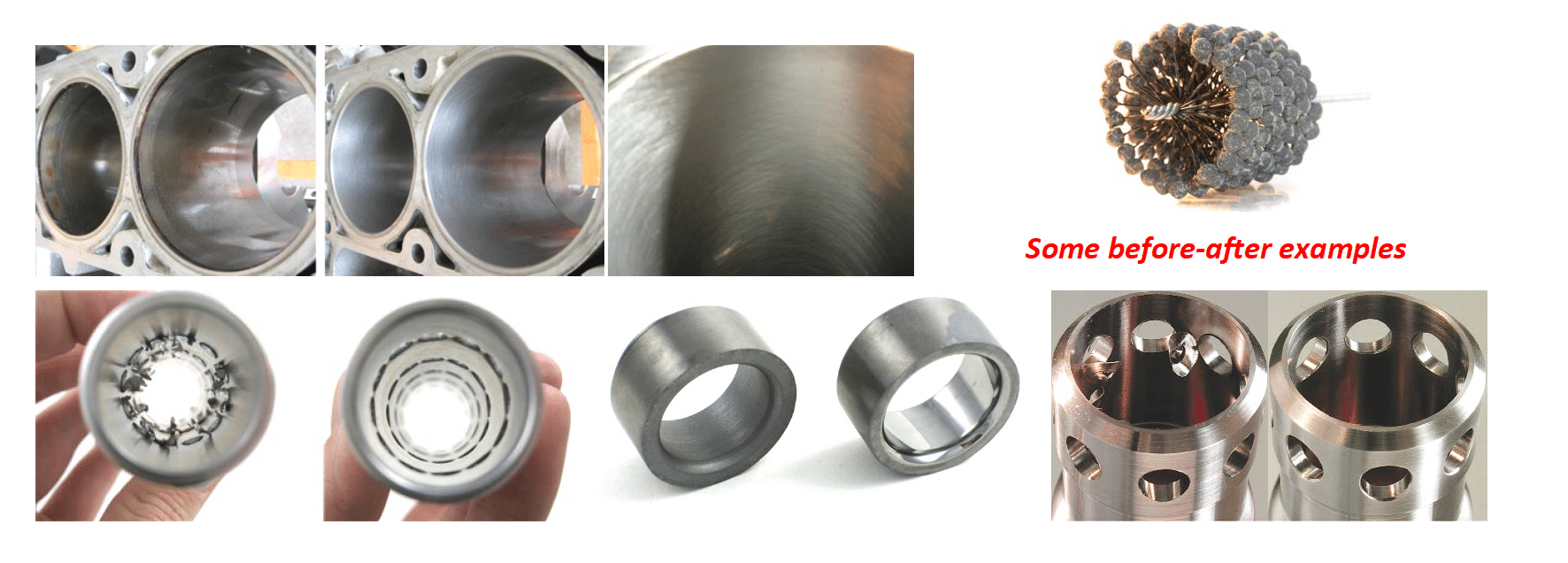

Processes examples

With the right choice of abrasive and grit from the wide range available, it is possible to achieve:

• Polishing-Superfinishing-Surface Roughness Correction: it is possible to reduce roughness and obtain a superfinish, achieving values below Ra 0.06 um even on materials with a hardness exceeding 80Hr.

Alternatively, it is possible to provide the required roughness to a surface that is too smooth, up to values of approximately Ra 2 um, still obtaining a surface with a cross-hatch “Plateau” finish. It is possible to standardize the surface finish by eliminating the marks from previous processes.

• Deburring: it is possible to achieve deburring or micro-deburring on the entry/exit edges of holes, intersecting holes, and channels, as well as edges of grooves or O-ring seats after drilling, turning, boring, grinding, lapping, etc.

• Radiusing: it is possible to round off the sharp edges that remain after boring, drilling, turning, grinding, etc.

• Bore post-processing: it can be used to uniformly remove material from a few microns or hundredths up to 0.1 mm on a bore without deforming it, and in certain cases, it can correct pre-existing deformations.

• Cleaning, descaling: thanks to its abrasive action, it is also an excellent tool for cleaning, deoxidizing, descaling, etc.