Compliance and advantages

KATO – Advanex

TECHNOLOGY THAT SIMPLIFIES THREADED INSERT USAGE AND MAKES IT SAFER

Introducing Tangless, KATO – Advanex has revolutionized the threaded insert market.

COMPLIANCE

Tangless inserts comply with aerospace and military standards NASM8846-33537-122076-124651-21209, NAS1130,

AS5272, ASME B18.29.1, NA0276, MA3379-3329-1565-1567, ecc and to the directives RoHs e DFARS.

Designed to meet the high standards of quality and safety in the military and aerospace sectors, their use has since

expanded to encompass all industrial applications.

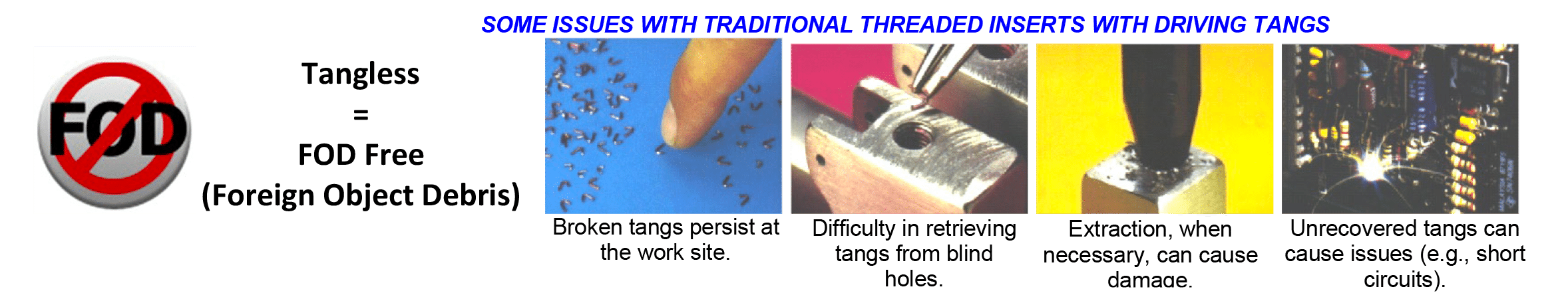

ADVANTAGES

No tang driver to be broken, retrieved, or lost.

The risk of short circuits, jams, or malfunctions caused by unretrieved tangs circulating during equipment operation is eliminated.

TIME SAVING – REDUCTION IN INSTALLATION COSTS

No tang driver to break. No time wasted on its retrieval. Eliminates the inconvenience of coil jump often caused by tang breakage with a punch. Bi-directional, having engagement on both sides, eliminating the need for orientation during installation.

HIGH QUALITY = NULLIFICATION OR MINIMIZATION OF REJECTION AND REPAIR TIME

QUICK AND NON-DESTRUCTIVE REMOVAL AND/OR REPLACEMENT

NO DAMAGE – MINIMIZATION OF DOWNTIME

If removal is necessary, it reduces to a simple unscrewing operation and is non-destructive. Easy replacement is possible in case of wear or for the self-locking model in the event of a decrease in braking values due to numerous unscrewing operations or the use of the “screw – self-locking threaded insert” joint as trim.

OTHER ADVANTAGES

They can be easily stacked to achieve non-standard lengths or with multiple self-locking features to achieve a very high braking torque.