LOCKING INSERTS KATO Advanex

Tangless inserts are available in standard (FR – Free Running) and self-locking (SL – Screw Locking) versions. The self-locking version applies a braking torque to the screw thread, preventing loosening due to vibrations or impacts. Self-locking threaded inserts eliminate the need for additional bulky locking systems. They are excellent in applications where adjustment screws are required, preventing the screw from moving from its position.

How do self-locking threaded inserts work?

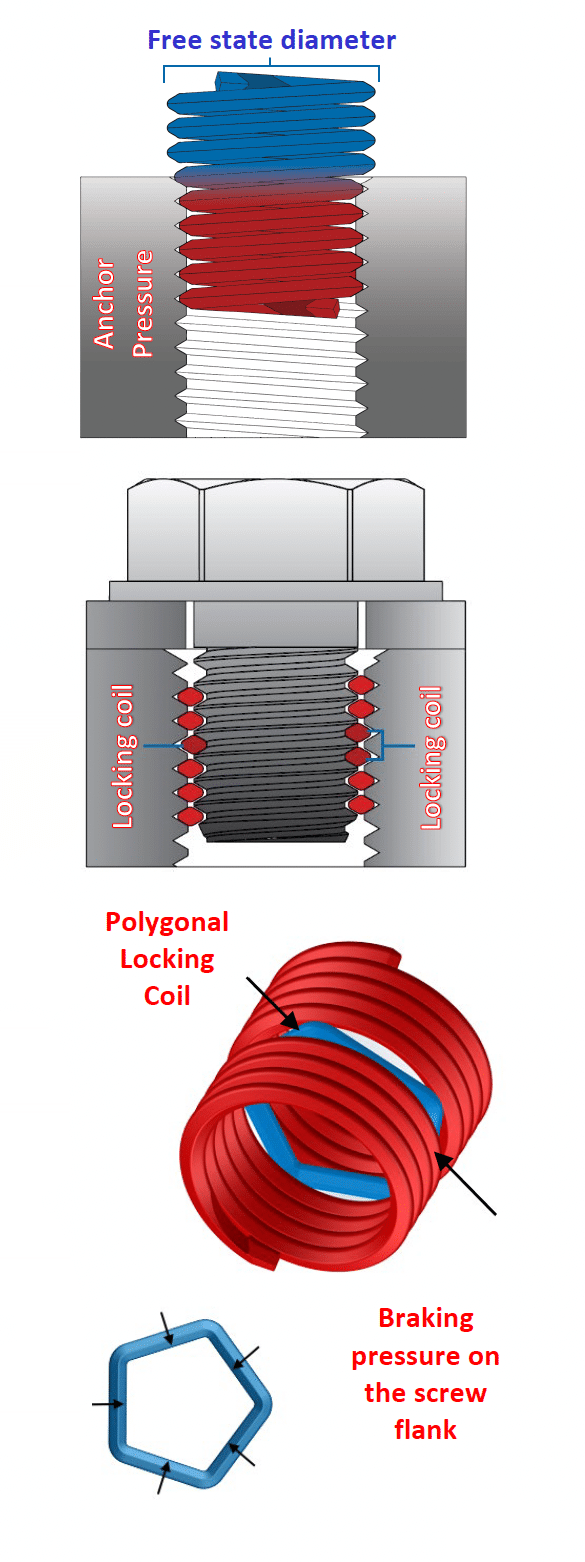

A common misconception when discussing Locking threaded inserts is that the insert anchors itself to its seat. Both the Free and Locking versions anchor by compression to the installation seat; the Locking version additionally applies a braking torque to the screw. Locking threaded inserts have one or more polygonal coils that, as the screw thread passes through, flex and exert pressure on the flanks of the threading, thereby maximizing the contact area.

Position of the locking polygonal coils

For lengths 1d, 1.5d, and 2d, the center of the locking coil or coils is equal to ½ the number of standard coils. For lengths 2.5d and 3d, the locking coil for inserts with a tang driver is positioned at the same distance from the tang as the 2d inserts, and for Tangless inserts without a tang driver, it is equal to ½ the number of standard coils.

Braking torque

KATO Advanex Locking inserts have braking torques in accordance with NASM8846 (UNC-UNF sizes) and MA1565 (metric sizes) that require the maintenance of specific braking values.

NASM8846 specifies that housing threads should be in 2024-T4 aluminum blocks with 3B class threads in accordance with NASM33537. MA1565 specifies that housing threads should be in 2024-T4 aluminum blocks with 4H class threads in accordance with MA1567. The screws used are 36-42Hrc with Cadmium plating.

To achieve maximum performance in terms of locking torque, it is recommended to use H4 or 3B taps to thread the insert housing and to check the threads with a go/no-go gauge.

Locking threaded inserts are colored in red for identification according to international standards. The coloring is achieved using dyes that do not alter tolerances and can be easily removed by washing with solvents or alcohol.

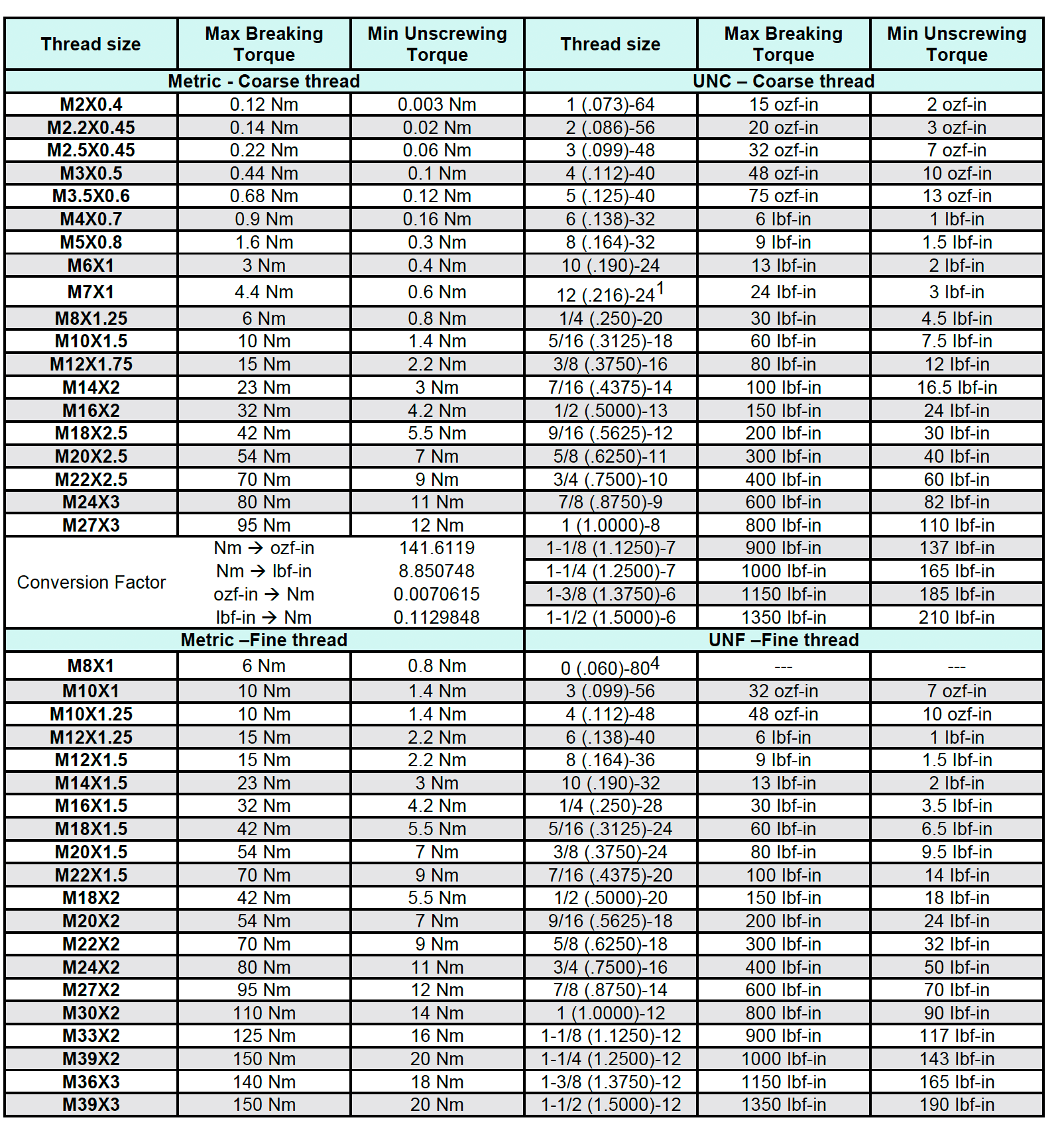

LOCKING THREADS BRAKING TORQUE