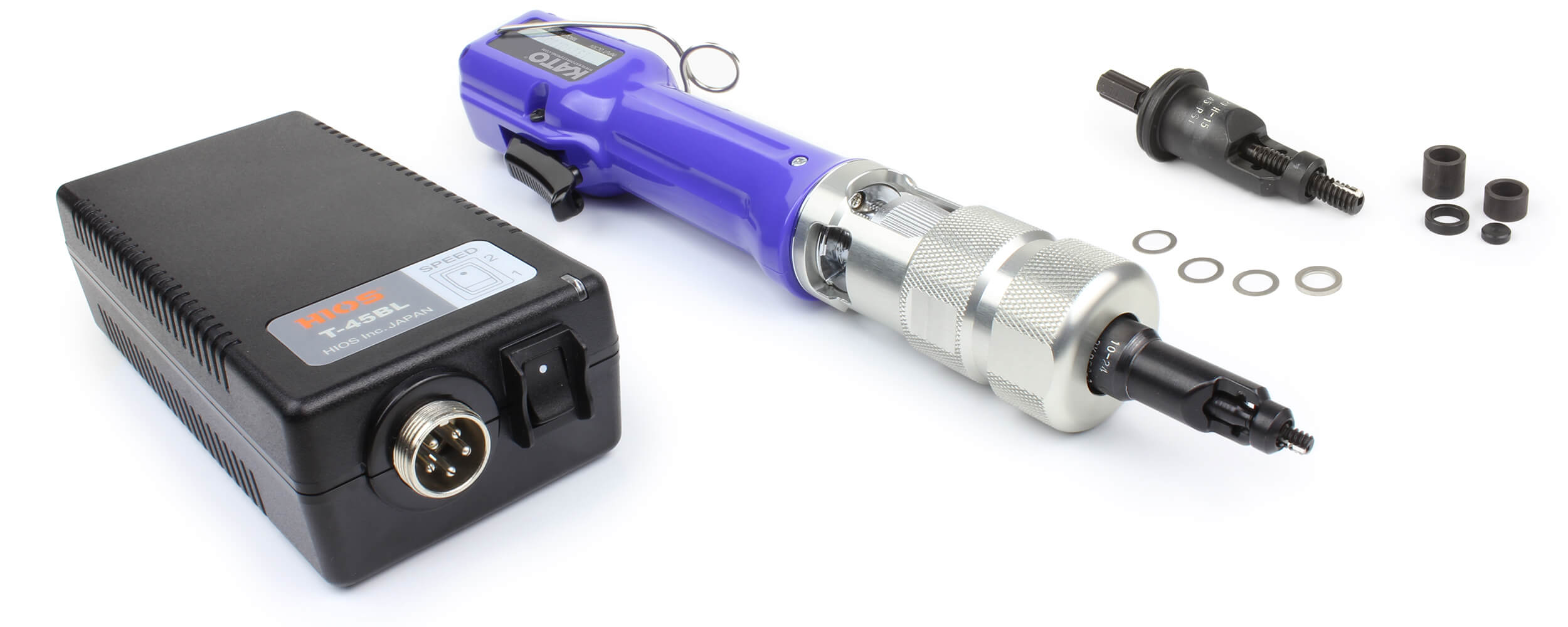

Complete set of equipment for hole preparation, tapping, inspection, and installation. These are precision tools and, if used with adequate care (meaning by controlling and adjusting the installation torques) they have a very long lifespan. The driving hook can easily reach over 10,000 installations; once worn, it can be replaced without the need to discard the entire tool, which can have a very high durability.

KFS-20 and KFS-25 ELECTRIC INSTALLATION TOOLS

Ideal for applications with medium to high installation volumes, the tool is lightweight, easy to use, and quiet. It has a clutch to prevent damage to the rods and automatic reverse for disengagement. It allows for quick change of the installation tool to quickly switch to installing a different size. It is used with 1/4HEX rod installation or removal tools.

- KFS-20 usage range: M2 – M6 and 2-56 – 1/4

- KFS-25 usage range: M4 – M12 and 6-32 – 1/2”

KFS-30 CORDLESS INSTALLATION TOOL

Ideal for applications with medium to high installation volumes, the tool is lightweight, easy to use, and quiet. It has a clutch to prevent damage to the rods and automatic reverse for disengagement. It allows for quick change of the installation tool to quickly switch to installing a different size. It is used with 1/4HEX rod installation or removal tools or prewinders..

KFS-20 & KFS-30 ELECTRIC INSTALLATION TOOL WITH PREWINDER

Combining the features of an electric tool with those of a pneumatic one, it is quiet and does not require compressed air. It allows for the installation of medium to high volumes of inserts, both on plastic strips and loose. From M2.5 to M6 and from 2-56 to 1/4″.

PNEUMATIC INSTALLATION TOOL

For the installation of medium to high batches using inserts on plastic strips. It is recommended to use the torque-adjustable clutch when installing threads from M2.5 to M4 and from 2-56 to 4-40.

GO-NO GO THREAD GAUGES – PRO KITS – TANGLESS

Threaded inserts acquire the tolerance class of the tapping on which they are installed. It is recommended to use taps with a class of 5H or 4H, especially for the installation of self-locking inserts, to obtain appropriate braking values. It is necessary to perform thread checks with a GO-NO GO thread gauge.